Benefits of Furans Testing

17th April 2024

Both oil and paper play a part in a transformer’s insulation properties and whilst a routine test on the fluid will indicate its overall condition, including di-electric strength, there is a further test available to ascertain the papers condition, their tensile strength: a Furans test.

Discovering degrading oil can be overcome by processing or replacing the oil. However, any degrading of the papers is irreversible. Along with routine and DGA testing of the transformer oil monitoring the Furans facilitates predicting any potential issues enabling preventative measures to be implemented, the planning for end of serviceable life or prior to any catastrophic failure of the transformer.

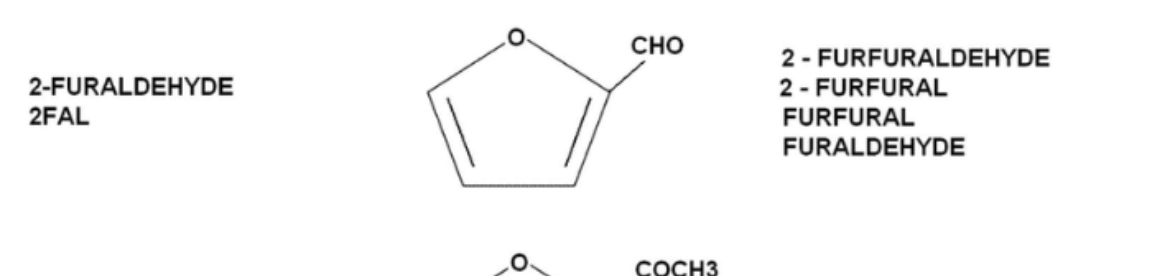

The papers are made of cellulose fibres; when these fibres are exposed to heat, oxygen, acid or moisture they begin to break down and this process produces Furans. Furans will only be produced by the cellulose degradation making testing for Furans an ideal indicator to the condition of the transformer’s paper insulation properties.

Measurement of this degradation is quantified by the estimated degree of polymerisation, DP for short. To determine the actual DP requires taking a physical sample of the papers for analysis, which is intrusive and requires an interruption to the supply. Such a process is more costly and possibly detrimental to the transformer, whereas testing for Furans can be accomplished from the same sample taken on a routine maintenance visit, thus saving the loss of supply and associated costs.

There are many different formulas which can be used for calculating the estimated DP, the Chendong’s model being considered the most appropriate to encompass any transformer with studies showing that there is a very good correlation between the estimated DP and actual DP when using this method.

In a new transformer the DP of the papers would typically be approximately 1000, so a DP of 750 would be interpreted as the papers having lost approximately 25% of their tensile strength. A DP reading of 200 or below is considered to indicate the end of reliable life of the papers.

Once a DP of 200 or less is obtained the transformer could still operate as normal. However there is a lot higher risk of failure especially should the transformer be subjected to an external stress, a mechanical shock, there being a ‘through’ fault on the network or the load suddenly changes. All of these increase the risk of failure at this point.

Although the frequency of Furans testing may vary depending on factors such as the transformers age or risk profile, it is worth showing consideration to put testing in place, establishing a base line and monitoring any change in trend is effective preventative maintenance.

It should be noted that if any remedial action has been taken on the transformer, such as changing of the transformer oil over the previous few years, this will give inaccurate estimations further giving cause to monitoring prior to establish any trend.

For more information on the services we offer please see our Factsheets page or alternatively give us a call and one of our engineers will happily talk things through in more detail with you.

News Stories

- High Voltage Equipment & Compliance

- PCB Regulations Changing

- Powering British Farming: EME Power Systems Installs Two New Transformers and High Voltage System to Boost Agricultural Output

- Faulty ACB

- Its Not Just One Man Busy In December!

- Christmas Cheer

- 21st Anniversary!

- WHO YOU GONNA CALL……

- Welcome Mark Baxter

- Overdue Maintenance

- University HV Fault

- Customer Feedback

- Larger Than Your Normal EV’s

- Taking the Biscuit

- Aftermath of Storm Babet

- Emergency Response to Storm Babet’s Disruption

- Welcoming Samantha Collishaw and Reducing Carbon Footprint

- Ardagh Glass Transformer Replacement

- Considering Voltage Management to Help Cut Bills?

- Graham Haydn-Davies Retirement

- LV Sub-Main Fault

- Cable Joint Failure

- Phil Shaw Retirement

- Directional Drilling

- Pre-Planned Maintenance

- Energy Savings Factsheet

- The Benefits of Carrying Out Planned Preventative Maintenance (PPM)

- EME Transformer Stock Saves the Day!

- PARTIAL DISCHARGE TESTING

- Storm Franklyn

- Helping to Mitigate the UK Energy Crisis

- EME Power Systems Helps Company To Join The Recycling Effort

- Christmas Time Switchgear Changes

- Out of Hours Peace of Mind

- EME Power Systems Fast Response for Major Food Manufacture

- Importance of Regular Intrusive Maintenance

- NHS Challenge

- Automated Packaging at Malvern Worcestershire

- Christmas Arrives Early

- Challenge Accepted

- Through these uncertain times...

- Hayley Paddock Joins EME Power Systems

- Challenging Times

- Low Carbon Electricity

- Our excellent installation teams complete essential works

- Fast Response

- Essential Maintenance

- Solution to a tricky transformer replacement

- It's A Cut!

- EME Power Systems Quarterly Update

- Infrastructure Upgrade

- EME Power Systems Continue As Normal

- It's Cold Inside

- Double transformer failure leads to double success

- Steve Harrison Joins the Company

- Class Cancelled

- Now For Something Slightly Different

- Go Green and Save Pounds

- Cable Fault Repair

- ACB

- Time For A Quick Change Around

- Lincoln Prison

- EME Power Systems Renewables

- An Early Summer Break - Out With The Old, In With The New

- EME Power Systems Midweek Break